Page 294 - 08-气源处理元件

P. 294

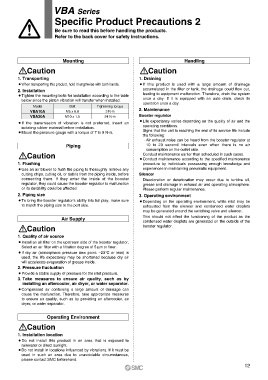

VBA Series

Specific Product Precautions 2

Be sure to read this before handling the products.

Refer to the back cover for safety instructions.

Mounting Handling

Caution Caution

1. Transporting 1. Draining

¡When transporting this product, hold it lengthwise with both hands. ¡If this product is used with a large amount of drainage

2. Installation accumulated in the filter or tank, the drainage could flow out,

¡Tighten the mounting bolts for installation according to the table leading to equipment malfunction. Therefore, drain the system

below since the piston vibration will transfer when installed. once a day. If it is equipped with an auto drain, check its

operation once a day.

Model Bolt Tightening torque

VBA10A M5 x 0.8 3 N·m 2. Maintenance

VBA20A M10 x 1.5 24 N·m Booster regulator

¡If the transmission of vibration is not preferred, insert an ¡Life expectancy varies depending on the quality of air and the

isolating rubber material before installation. operating conditions.

¡Mount the pressure gauge with a torque of 7 to 9 N·m. Signs that the unit is reaching the end of its service life include

the following:

· Air exhaust noise can be heard from the booster regulator at

Piping 10 to 20 second intervals even when there is no air

consumption on the outlet side.

Caution ¡Conduct maintenance according to the specified maintenance

Conduct maintenance earlier than scheduled in such cases.

1. Flushing procedure by individuals possessing enough knowledge and

¡Use an air blower to flush the piping to thoroughly remove any experiences in maintaining pneumatic equipment.

cutting chips, cutting oil, or debris from the piping inside, before Silencer

connecting them. If they enter the inside of the booster Discoloration or deterioration may occur due to turbine oil,

regulator, they could cause the booster regulator to malfunction grease and drainage in exhaust air and operating atmosphere.

or its durability could be affected. Please perform regular maintenance.

2. Piping size 3. Operating environment

¡To bring the booster regulator’s ability into full play, make sure ¡Depending on the operating environment, white mist may be

to match the piping size to the port size. exhausted from the silencer and condensed water droplets

may be generated around the switching valve and silencer.

Air Supply This should not affect the functioning of the product as the

condensed water droplets are generated on the outside of the

Caution booster regulator.

1. Quality of air source

¡Install an air filter on the upstream side of the booster regulator.

Select an air filter with a filtration degree of 5 μm or finer.

¡If dry air (atmospheric pressure dew point: –23°C or less) is

used, the life expectancy may be shortened because dry air

will accelerate evaporation of grease inside.

2. Pressure fluctuation

¡Provide a stable supply of pressure for the inlet pressure.

3. Take measures to ensure air quality, such as by

installing an aftercooler, air dryer, or water separator.

¡Compressed air containing a large amount of drainage can

cause the malfunction. Therefore, take appropriate measures

to ensure air quality, such as by providing an aftercooler, air

dryer, or water separator.

Operating Environment

Caution

1. Installation location

¡Do not install this product in an area that is exposed to

rainwater or direct sunlight.

¡Do not install in locations influenced by vibrations. If it must be

used in such an area due to unavoidable circumstances,

please contact SMC beforehand.

12